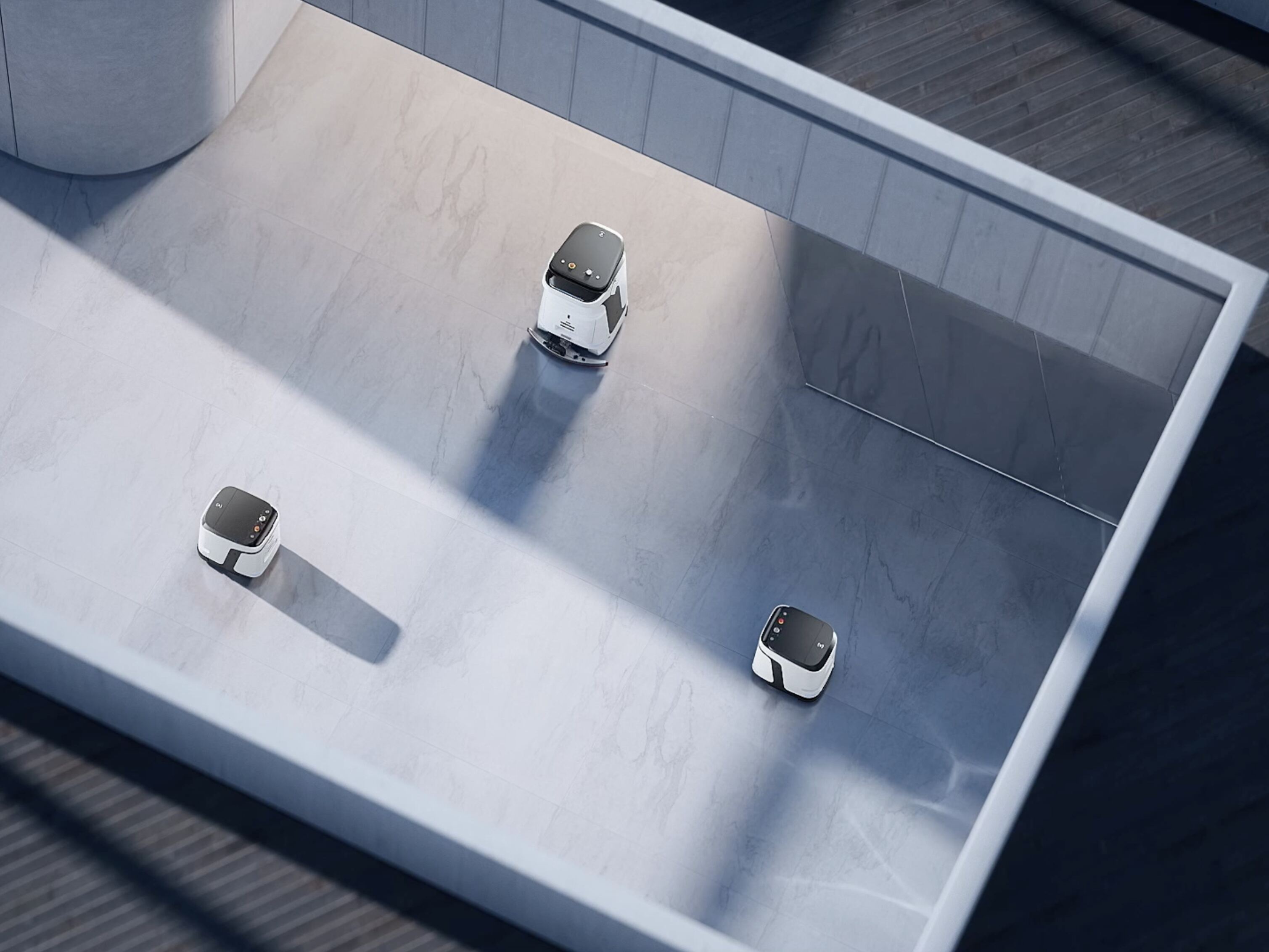

industriae purgatio robot

Robotae purgationis industrialis notabile progressum in technologia automationis custodiae repraesentant, coniunctione eximiae technologiae AI et ingenii mechanici solidi ut solutiones purgationis efficaces et constantes praestent. Hi machinae autonomae sensoribus et systematibus navigationis provisae sunt, ut per se in variis environmentalibus industrialibus operari queant, sive in magazinis sive in fabricis. Hi roboti technologiae purgationis novissimae utuntur, interiectis iactibus aquae ad altam pressionem, harundinabus specialibus, et systematibus vacuum, ad varias formas sordis et detriti tollendas. Programmare potest ut certas vias et tempora purgandi sequantur, ad varias distributiones et obstantia adaptandi. Hi machinae praeditae sunt praesidiis tutelae ut detectio collisionis et machinae arrestiurgenti, ut cum operariis humanis tuta operatione iungantur. Hi roboti per longos periodos sine intermissione operari possunt, paucissima interventione humana praeter custodiam et praeparationem ordinariam. Superficies varias a concreto levi ad pavimenta industrialia texturata purgare possunt, et tam opere siccis quam umidis fungebantur. Hi systemata solent praemunita esse facultatibus monitoriae remotae, ut magistri aedificiorum per software interfaces progressum purgationis et metrices operationis in tempore reali custodire queant.